Pozzolans

Improving performance and durability of the Nation’s infrastructure

What They Are

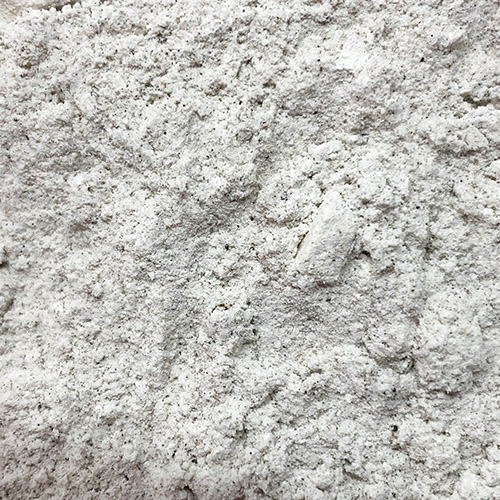

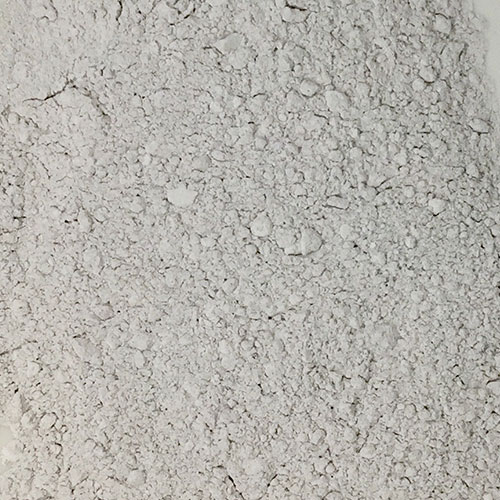

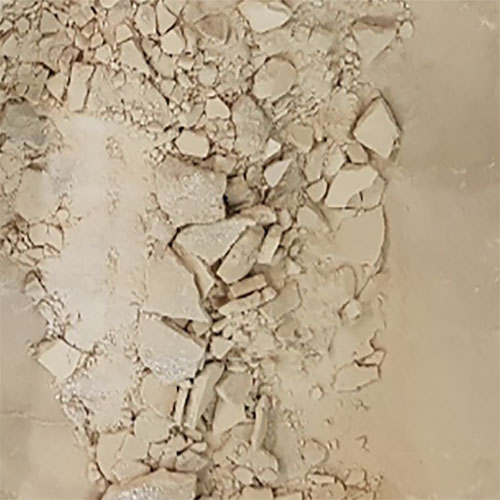

Pozzolans include a broad category of materials, both naturally occurring and by- products of various modern manufacturing processes but can be generally defined as being mainly siliceous or silico-aluminous material that will, in finely divided form and in the presence of moisture, chemically react with calcium hydroxide at ordinary temperatures to form compounds having cementitious properties.

Typical pozzolans found across Australia fall into either ‘manufactured’ or ‘natural’ sources. Any material having pozzolanic properties are silicate-based materials that react with the calcium hydroxide generated by hydrating cement to form additional cementitious materials.

What They Do

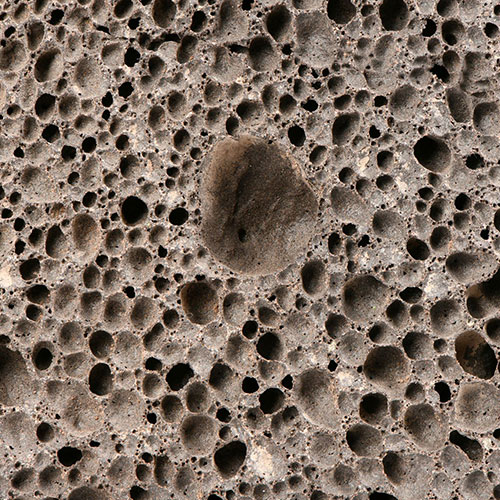

As silicate-based materials, pozzolans will react with the calcium hydroxide generated by hydrating cement to form additional cementitious materials. Calcium hydroxide (lime) accounts for up to 25% of the hydrated Portland cement but it does not contribute to the concrete’s strength or durability. Pozzolans combine with the lime to produce additional calcium silicate hydrate, the material responsible for holding concrete together, but more importantly improve concrete's plastic and hardened properties including durability.

Strength

and durability of the concrete can be improved

Density

of the concrete is increased through pozzolan’s filler effect

Efflorescence

formation of the concrete is reduced and controlled

Propensity

for alkali-silica reaction is decreased, or even virtually eliminated