Optimising Glass Powder Pozzolan Ratio for Eco-Friendly Paving Blocks

Found 12 km off the Sriracha shore, Si Chang Island stands as a popular tourist destination in Chonburi, attracting 486,993 visitors in 2017. Despite its appeal, the island encounters solid waste management challenges.

Researchers have conducted a recent study where glass powder pozzolan and municipal incinerated bottom ash (MIBA) were introduced to concrete mixes to create paving blocks, with the hopes of developing an environmentally friendly product that reduces carbon emissions and waste materials on the Island.

15 different mixes were sampled, using a 1:3 cement to aggregate ratio and a 0.5 water-to-cement ratio. Glass powder pozzolan was used to substitute cement and 0, 10 & 20% weight. MIBA was used as an aggregate substitute at 0, 10, 20, 30, & 40% volumes.

Two groups were formed, with one being cured with water for 28 days, and the other for 90 days.

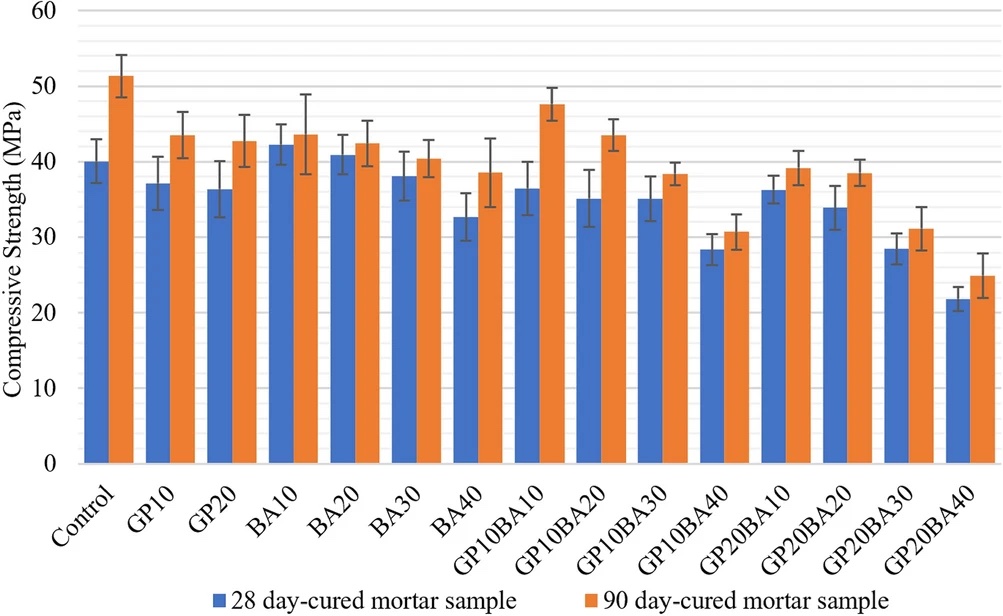

After 28 days of curing, BA10 (Municipal Incinerated Bottom Ash, 10%) and BA20 (MIBA, 20%) had compressive strengths of 42.28 and 40.92 MPa, higher than the standard for interlocking concrete block (40MPa) according to TIS 827-2531.

After 90 days, GP10BA10 (Glass Powder, 10% - Municipal Incinerated Bottom Ash, 10%), BA10, GP10, GP10BA20, GP20, BA20, & BA30 had compressive strengths of 47.62, 43.63, 43.51, 43.48, 42.73, 42.40, and 40.40 MPa respectively, which also meets the TIS standards.

See graph below.

Comparative compressive strength graph of mortar samples cured for 28 & 90 days.

The best ratio of interlocking paving blocks in terms of mechanical performance was found to be glass powder 10% for cement substitution and municipal incinerated bottom ash 10% for sand substitution.

The glass powder was sourced from a waste recycling facility by crushing glass waste using a ball mill and then sieved to obtain desired fineness. MIBA was obtained from the incinerator on the Island in the Chonburi province of Thailand which was a mixture of fly ash and bottom ash.

Substituting these waste materials will allow for a more environmentally friendly product, as well as reducing the amount of waste material that is found on Si Chang Island, giving locals, and travelling tourists a greater experience when visiting.

___

View the full report HERE

Article: Kumpueng, P., Phutthimethakul, L. & Supakata, N. Production of Cement mortars from glass powder and municipal incinerated bottom ash. Sci Rep 14, 1569 (2024).